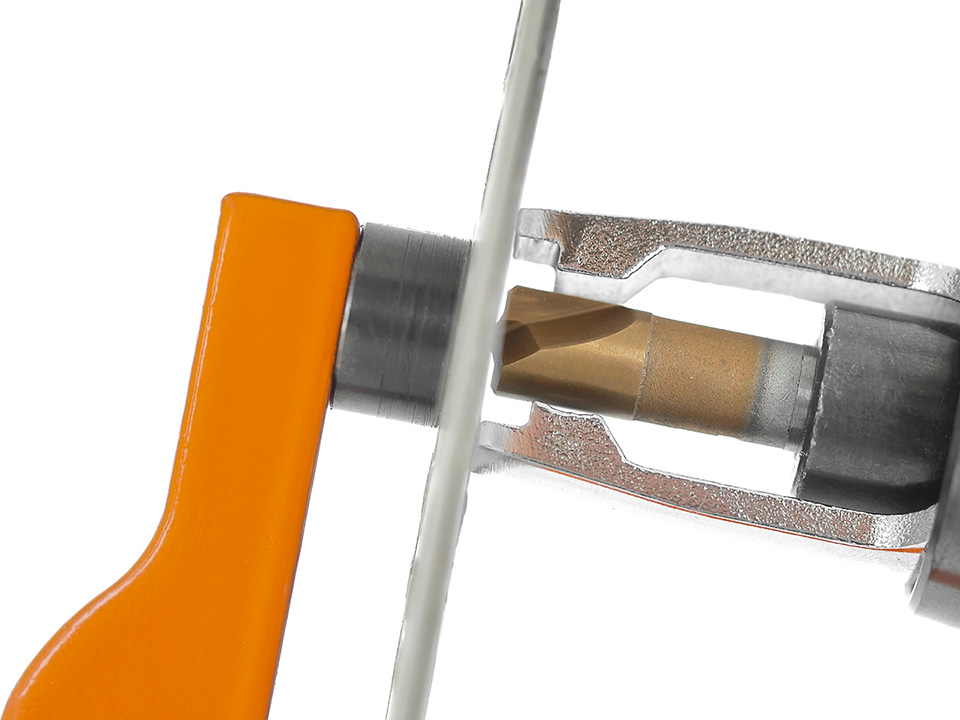

Spot weld drilling machine FASTDRILL

Our award-winning spot weld drilling machine.

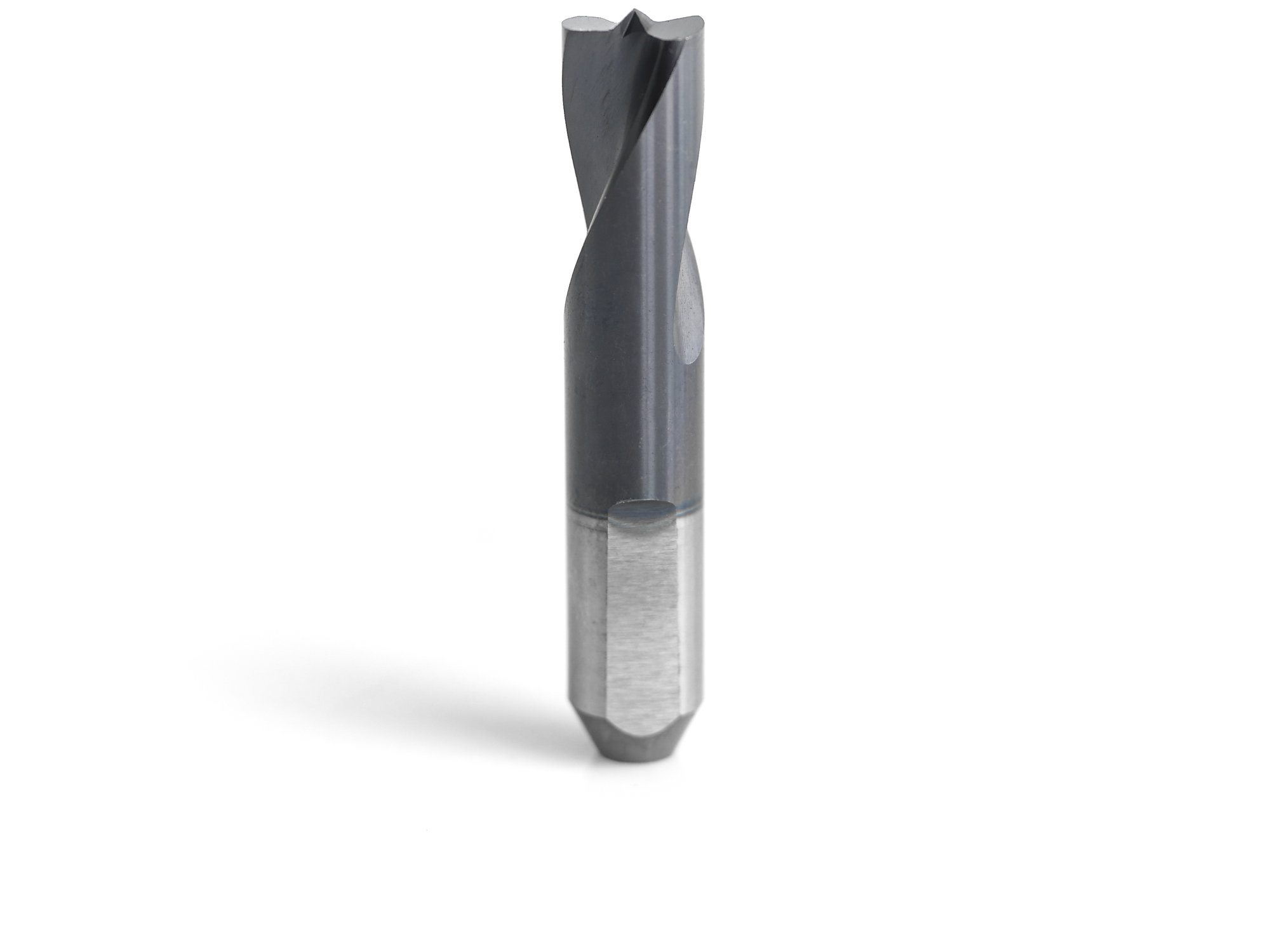

FASTDRILL is designed to solve spot welds — even in high-tensile steels. During development of Fastdrill a pneumatic and machanic adjustable feed have been combinaded for the first time. This combination increases the contact pressure of the drill of 60 kg up to 240 kg. Standard devices generate a pure pneumatic contact pressure of max. 150 kg. Another innovation is Fastdrill only start drilling if the drill is in contact with the surface and placed in the right position. This is specially important by usage of carbide drills, because they are extremly strong (3100 Vickers), but against impacts very sensitive. The Fastdrill is suitable for high-tensile and normal steel. Even lifetime of carbide drills is increased by many times. Similarly it is with normal and coated HSS-drills.

BENEFITS

-

Starts only by contacting metal

-

Easy to handle

-

Aproved Spot-weld solver

-

For normal and high-strenght steel

-

Precise cut

SCOPE OF DELIVERY

-

FASTDRILL Spot Weld Drilling Machine

-

Counterholder, small

-

pinn spanner

-

Case with Inlay

-

Manual

TECHNICAL DATA

| Compressed air: | max. 6,2 bar |

| rpm: | 1000 |

| Connection: | 1/4” |

| Contact preassure: | ca. 240 kg |

| Noise level: | 82 dba |

| Air consumption: | 175 l/min./ 6 CFM |

| Drill bit holder size: | 8 mm |

| Vibration level (handle): | 0.233 m/s² |

Downloads for Spot weld drilling machine FASTDRILL

Accessories and spare-parts More products for Spot weld drilling machine FASTDRILL

These products could be interesting for you