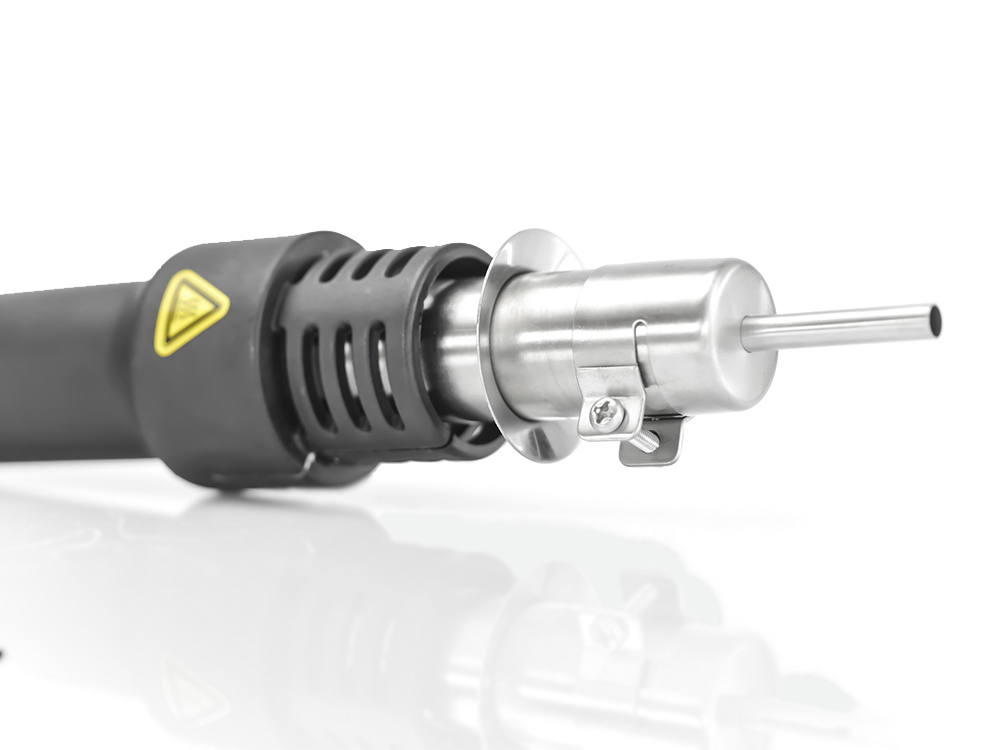

Plastic Welding System PLASTOFUSED 2.0

A new era of plastic welding has just begun.

Our new quick and easy solution for plastic-repair. Our new PLASTOFUSED 2.0 is equipped with a LCD-display which shows the set temperature and the real temperature. We can reach higher temperatures by using a lower air volume as this is the key to be able to achive a good bonding. With this we get the plastic faster up to its own melding flow index (MFI) which then makes it ideal for bonding. With the special designed flat welding strip we created a tool for a quick, simple and high quality plastic-repair.

BENEFITS

-

Quick & efficiently

-

Easy to handle, low training effort

-

Ideal mixture of air pressure and temperature

-

Incl. Trolley with one big tray

-

High-quality main-housing

-

Modern design interacts with high user-friendliness

-

LCD display with clear control panel

-

Wide range of accessories extends the field of application

-

Different Melting-Strips

![]()

SCOPE OF DELIVERY

Depending on your requirement, we provide three different Versions of PLASTOFUSED:

The PLASTOFUSED ECO includes the single unit and one package of PP-EPDM and ABS Melting-Stripes.

The PLASTOFUSED BASIC is our extensive kit. It contains the PLASTOFUSED 2.0 unit with removable hose package (2m). Additionaly it contains accessories like the special flat-nose plier. As well a pneumatic two speed grinder is included for slow grinding of the material without melting it.

The PLASTOFUSED MOBILE-BASIC contains beside the BASIC-Version a trolley with tray. In this way you recive a complete station for plastic repair. Of course there is enough place for more smart repair tools (such as PLASTOCLIP with spacer).

TECHNICAL DATA

| Operating voltage: | 230 V~ |

| Power: | 320 W / 1,49 A |

| Adjustable temperature: | 160…480 °C / 320…896 °F |

| Display: | Double-spaced LCD |

| Nozzle ø: | 5 mm |

| Hose package (basic): | 2000 mm / removable |

| Hose package (eco): | 1000 mm |

| Protection class (basic): | IP 42 |

| Protection class (eco): | IP 40 |

| Manufacturer: | KAMATEC |

| Made in: | Germany |

Downloads for Plastic Welding System PLASTOFUSED 2.0

Accessories and spare-parts More products for Plastic Welding System PLASTOFUSED 2.0

These products could be interesting for you